产品型号:QUICK TURN 6G

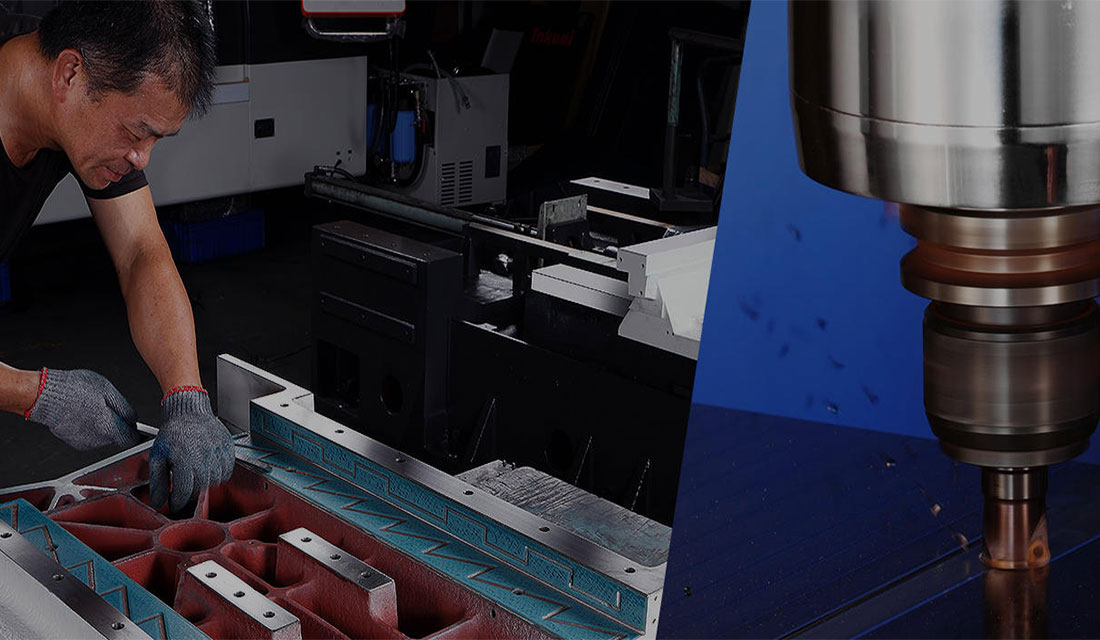

基本信息:车削是用于回转体零件的加工,采用的是工件旋转,刀具沿着线性方式运动。通常由车床来对一工件进行削减外圆尺寸。将工件加工到特定尺寸并且获得光洁的加工表面就是一个典型。带有CNC装置的车床称谓车削中心。复杂的车削中心还可以进行多种铣削和钻削加工。

详细说明:查看

产品说明

INSTALLATION

MACHINE DESCRIPTION:The QUICK TURN 6G CNC Chucker Turning Center features a compact design for small workpieces. As a chucker configuration, the machine offers the versatility of either three-jaw or collet chucks for high efficiency turning capability. The Gang Plate style tooling systems eliminates turret indexing to keep machining cycles to a minimum. Optional Gantry Loader (GL) systems provide the ability for un attended operation to maximize spindle utilization and reduce cost per piece ratios. MACHINE CHARACTERISTICS:

|