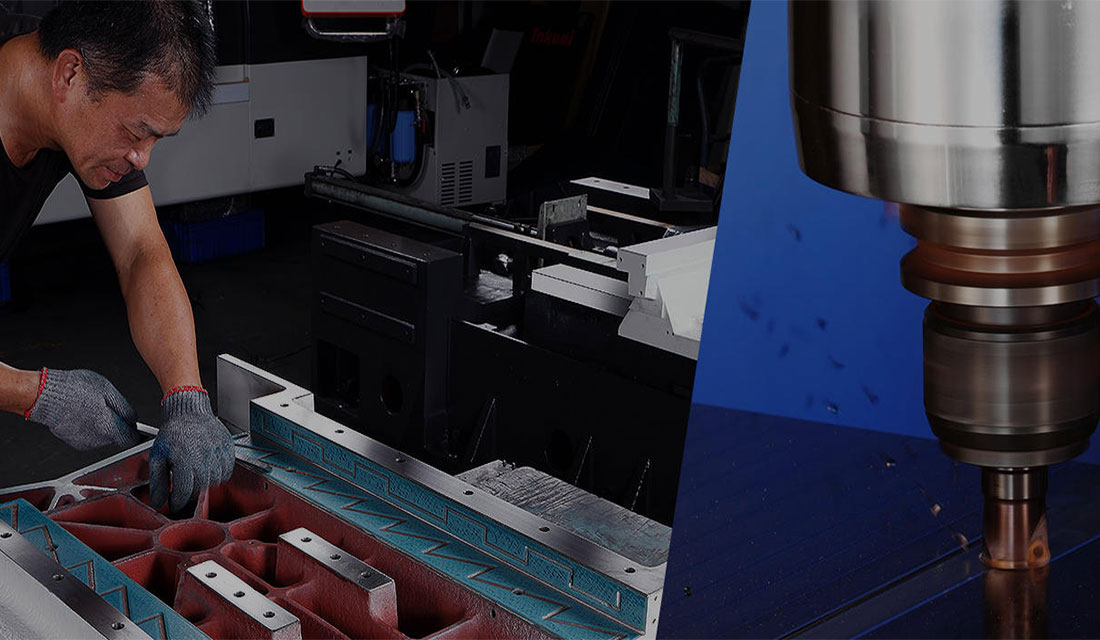

基本信息:车削是用于回转体零件的加工,采用的是工件旋转,刀具沿着线性方式运动。通常由车床来对一工件进行削减外圆尺寸。将工件加工到特定尺寸并且获得光洁的加工表面就是一个典型。带有CNC装置的车床称谓车削中心。复杂的车削中心还可以进行多种铣削和钻削加工。

详细说明:查看

INSTALLATION

MACHINE DESCRIPTION:The SLANT TURN NEXUS 600 CNC is a powerful, heavy-duty,high torque, big bore Turning Center for large part turning applications such as oil field pipe /casings, pipeline control valves, turbine components, and aircraft engine parts. The STN600 offers maximum machining lengths up to 160", and depending on chuck size, maximum machining diameters to 36", for long, large-diameter parts. The standard spindle bore is 14.7" diameter and can handle large diameter pipe and other components that required front and rear chucking. MACHINE CHARACTERISTICS:

|

PRODUCT

| Specification | 中心距 - 2000U in | 中心距 - 3000U in | 中心距 - 4000U in | |

| 加工能力 | 最大回转直径 | 1040 mm / 40.94 in | 1040 mm / 40.94 in | 1040 mm / 40.94 in |

| 最大加工直径 | 910 mm / 35.830 in | 910 mm / 35.830 in | 910 mm / 35.830 in | |

| 最大加工长度 | 2009 mm / 79.090 in | 3144 mm / 123.780 in | 4033 mm / 158.780 in | |

| 主轴 | 卡盘尺寸 | 21 in | 21 in | 21 in |

| 最大转速 | 500 rpm | 500 rpm | 500 rpm | |

| 电机功率 (30 分钟额定) | 45 kw / 60.0 hp | 45 kw / 60.0 hp | 45 kw / 60.0 hp | |

| 上刀塔 | 刀具数量 | 12 | 12 | 12 |

| 进给轴 | 行程(X轴) | 465 mm / 18.31 in | 465 mm / 18.31 in | 465 mm / 18.31 in |

| 行程(Z轴) | 2165 mm / 85.24 in | 3300 mm / 129.92 in | 4190 mm / 164.96 in | |

| 行程(W轴) | 2083 mm / 82.01 in | 3218 mm / 126.69 in | 3890 mm / 153.13 in | |