基本信息:车削是用于回转体零件的加工,采用的是工件旋转,刀具沿着线性方式运动。通常由车床来对一工件进行削减外圆尺寸。将工件加工到特定尺寸并且获得光洁的加工表面就是一个典型。带有CNC装置的车床称谓车削中心。复杂的车削中心还可以进行多种铣削和钻削加工。

详细说明:查看

INSTALLATION

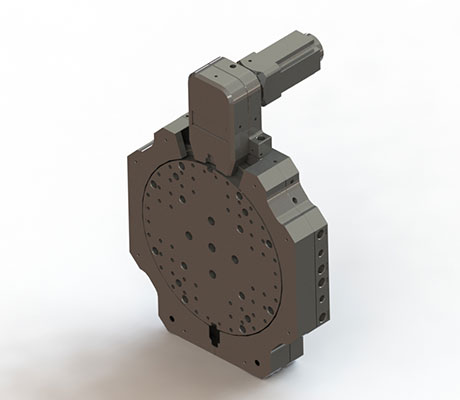

MACHINE DESCRIPTION:The MEGATURN NEXUS 1600M CNC vertical turning center excels in the heavy-duty cutting of large, low-to-medium profile, tough-to-machine workpieces such as those found in the construction machinery and jet engine industries. With a machine configuration that includes rotary tool milling (M) capability, the MEGATURN NEXUS 1600M can combine turning and secondary machining operations to improve accuracy and increase productivity through reduced set ups and workpiece handling. MACHINE CHARACTERISTICS:

|